Specification (power) selection guide for diesel generators

Selecting the right diesel generator is a critical decision for ensuring reliable power supply in emergencies or for prime operations. A generator that is undersized will fail under load, while an oversized one leads to unnecessary capital expense, higher fuel consumption, and increased maintenance. This guide outlines the key steps to accurately determine the specifications and power rating you need.

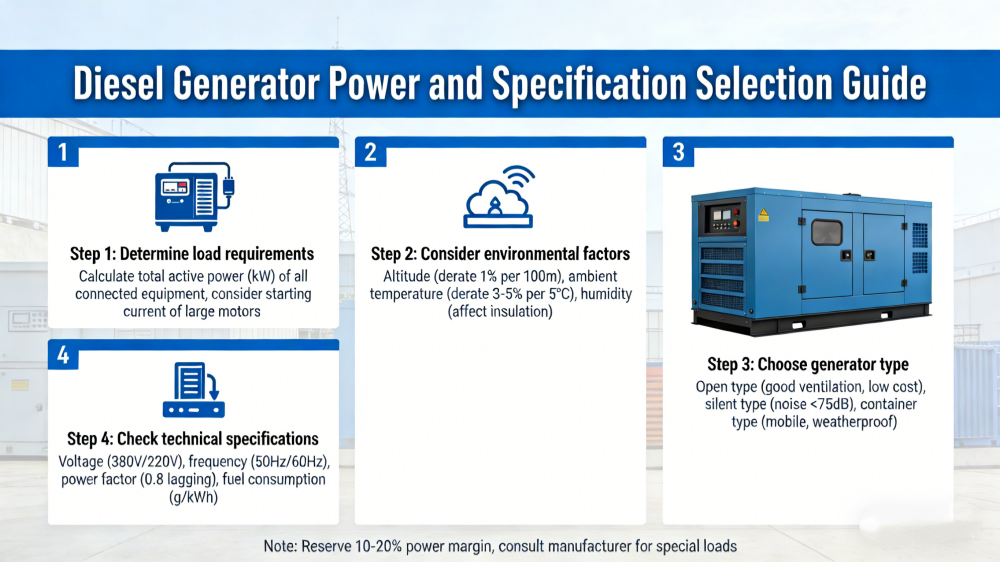

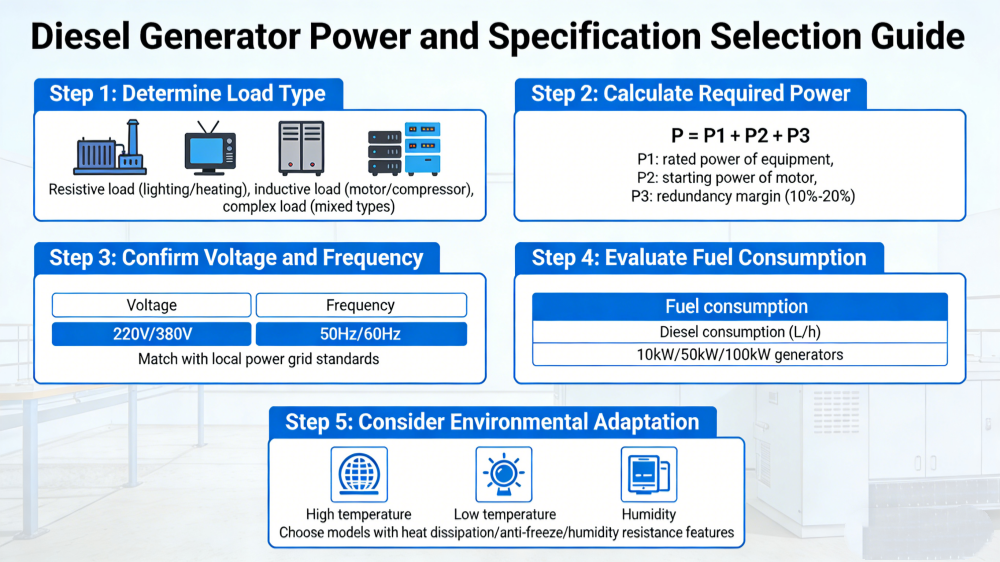

Step 1: Assess Your Power Requirement (The Most Crucial Step)

The foundation of your choice is calculating the total electrical load the generator must support.

List All Appliances/Equipment: Create an inventory of everything you plan to power simultaneously.

Distinguish Between kW and kVA:

kW (Kilowatts) is the measure of real power—the actual power doing the work.

kVA (Kilovolt-Amperes) is the measure of apparent power.

The relationship is: kW = kVA × Power Factor. Generators are often rated in kVA, but equipment ratings are usually in kW. A standard power factor for sizing is 0.8. For example, a 100 kVA generator at a 0.8 PF can deliver 80 kW of usable power.

Account for Starting Currents: Electric motors (in pumps, air conditioners, refrigerators) require significantly more power to start (up to 3-7 times their running wattage) than to run. This surge or inrush current is the most common cause of generator overload. You must factor in the highest starting load among your equipment.

Calculate Total Load:

Running Wattage: Sum the running wattage of all items.

Starting Wattage: Identify the device with the largest starting surge and add that extra surge amount to the running total of the other items.

Use a Formula: Total Required Generator Power = (Sum of Running kW) + (Largest Starting Surge kW)

Example: Running a 5kW water pump (surge: 15kW), 3kW of lights, and 2kW of electronics.

Running total: 5 + 3 + 2 = 10kW

Add the pump’s surge (15kW – 5kW = 10kW extra surge).

Estimated Required Power: 10kW (running) + 10kW (surge) = 20kW.

In kVA (at PF 0.8): 20kW / 0.8 = 25 kVA.

(View models of 50kw-2000kw diesel generator sets: List of 50kw-2000kw diesel generators)

Step 2: Define Your Application Type

The generator’s duty cycle dictates its rating:

Standby/Emergency Power (ESP): For backup during grid outages. Typically rated to run for short durations (e.g., 50-200 hours per year) with a variable load. It can handle the full power rating only for a limited time (e.g., 1 hour in 12).

Prime/Continuous Power (PRP): For the main power source where there is no grid, or for long, uninterrupted operation. Rated to run indefinitely at a variable load with a maximum output available 24/7. The same physical generator will have a lower kW rating in prime mode than in standby mode.

Continuous (COP): For a constant 100% load, 24/7. This is the most demanding application.

Always choose a generator based on its Prime or Continuous rating for long-term use, not its higher Standby rating.

Step 3: Choose the Generator Type

Open Frame/Canopy: Standard industrial set, requires installation in a dedicated, ventilated room or enclosure. More customizable.(view:Open frame diesel generator set style)

Soundproofed/Enclosed Canopy: Integrated canopy significantly reduces noise (typically to 70-80 dB(A) at 1 meter). Ideal for urban sites, hospitals, or events.(view:Silent diesel generator)

Mobile Trailer-Mounted: Generator and fuel tank mounted on a road-legal trailer for complete mobility between job sites.(view:Mobile trailer type diesel generator set)

Step 4: Consider Key Technical & Site Specifications

Voltage and Phase: Match your facility’s supply (e.g., 120/240V single-phase for homes/small businesses; 208/480V three-phase for industrial plants).

Fuel Type & Tank Size: Diesel is standard for durability and efficiency. Consider fuel consumption at your typical load and size the base tank for your required autonomy (e.g., 8, 12, 24 hours of run time).

Cooling System: Air-cooled for smaller units (<~30 kVA); liquid-cooled (radiator) for larger, more durable, and continuous-running units.

Alternator (Generator End) Quality: Look for brands with Class H insulation, brushless design, and automatic voltage regulation (AVR) for stable power quality sensitive to electronics.

Control Panel: Basic models offer start/stop and gauges. Advanced panels provide automatic mains failure (AMF) functionality for auto-start on blackout, remote monitoring, and data logging.

Site Conditions: Altitude and temperature drastically affect performance. Engines derate (lose power) at high altitudes and in high ambient temperatures. Consult the manufacturer’s deration charts.

Step 5: Plan for the Future

Add a 10-25% power margin to your calculated load. This cushion accommodates future additions, avoids constant 100% loading (which extends engine life), and provides a safety buffer for calculation errors.

Conclusion: Seek Professional Guidance

While self-assessment is a good start, consulting with a certified electrical engineer or a reputable generator supplier is highly recommended. They can perform a detailed load audit, model starting sequences, and recommend a model from a reliable manufacturer (e.g., Caterpillar, Cummins, Generac, Kohler) that balances performance, fuel efficiency, and total cost of ownership. Remember, the goal is to find a generator that is reliably adequate, not just the cheapest or the largest.